- Home

- Products

- Horizontal Directional Drilling

- HDD Drill Pipe

- HDD Drill Pipe (Forged Type)

HDD Drill Pipe (Forged Type)

China Compatible HDD Drill Pipe| Model Compatibility | Drill pipe Form | OD of the Tube (mm) | Wall Thickness of Tube (mm) | OD of the Joint (mm) | Thread Type | Pin Length (mm) | Working Length (m) | Recommend Connection Torque (N.m) | Bend Radius (m) | Tempering and Quenching Grade |

| 50(2'') | Forged One-piece | 50 | 6.5 | 57 | ZD50 | 63.5 | 2.5 | 2700 | 33 | S135 |

| 60.3 (2 3/8'') | Forged One-piece | 60.3 | 7.5 | 67 | ZD60 | 70 | 3 | 3500 | 38 | S135 |

| 73 (2 7/8'') | Forged One-piece | 73 | 8 | 80 | NC23 | 85 | 3 | 5500 | 46 | S135 |

| 73 (2 7/8'') | Forged One-piece | 73 | 8 | 80 | NC23 | 76.2 | 3 | 5500 | 46 | S135 |

| 73 (2 7/8'') | Forged One-piece | 73 | 10 | 87 | NC26 | 85 | 3 | 6300 | 55 | S135 |

| 76 (3'') | Forged One-piece | 76.2 | 10 | 87 | NC26 | 85 | 3 | 6300 | 55 | S135 |

| 83 (3 1/4'') | Forged One-piece | 83 | 9.19 | 92 | ZD80 | 88.9 | 3 | 8800 | 59 | S135 |

| 89 (3 1/2'') | Forged One-piece | 88.9 | 9.35 | 105 | NC31 | 88.9 | 4.5 | 9200 | 59 | S135 |

| 102 (4'') | Friction Welding | 101.6 | 9.19 | 127 | NC38 | 112 | 6 | 14800 | 98 | S135 |

| 114 (4 1/2'') | Friction Welding | 114.3 | 9.19 | 127 | NC38 | 110 | 6 | 19000 | 105 | S135 |

| 114 (4 1/2'') | Friction Welding | 114.3 | 9.19 | 139.7 | NC40 | 126.3 | 6 | 19000 | 105 | S135 |

| 114 (4 1/2'') | Friction Welding | 114.3 | 9.19 | 158.8 | NC46 | 126.3 | 6 | 25000 | 105 | S135 |

| 127 (5'') | Friction Welding | 127 | 9.19 | 168.3 | NC50 | 126.3 | 6 | 45000 | 115 | S135 |

| 127 (5'') | Friction Welding | 127 | 9.19 | 168.3 | NC50 | 126.3 | 9.6 | 45000 | 115 | S135 |

| 140 (5 1/2'') | Friction Welding | 139.7 | 10.54 | 190.5 | 51/2FH | 139 | 9.6 | 65050 | 120 | S135 |

| 168 (6 5/8'') | Friction Welding | 168.3 | 10.54 | 215.9 | 6 5/8FH | 127 | 9.6 | 86000 | 140 | S135 |

| Model of the rig | Connection | OD of the Tube (mm) | Wall Thickness (mm) | OD of the joints/upset (mm) | Working Length (mm) | Tempering and Quenching Grade | Min Bending Radius (m) | Max Torque (N.m) |

| D6×6 | FS1#200 | 38 | 5.5 | 48 | 1829 | S135 | 17.47 | 1220 |

| D7×11, D10×15 S3 | FS1#200 | 42.2 | 6 | 48 | 1829 | S135 | 29 | 2040 |

| D10×14, D10×15 | FS1#200 | 42.2 | 6 | 48 | 3048 | S135 | 29 | 2040 |

| D16×20A, D16×22 Series II D20×22 S3 | FS1#250 | 48.26 | 6 | 54 | 3048 | S135 | 30 | 2720 |

| D20×22A, D20×22 Series II D20*22 S3 | FS1#400 | 52.4 | 6.5 | 57 | 3048 | S135 | 31 | 3536 |

| D24×40,D24×40A, D24×40 Series II, D23 × 30 S3 D24×40 S3 | FS1#600 | 60.3 | 7.1 | 66.7 | 3048 | S135 | 33 | 5440 |

| D40×40 | FS1#600 | 60.3 | 7.1 | 66.7 | 4572 | S135 | 33 | 5440 |

| D33×44, D36×50, D36 ×50 Series II | FS1#650 | 60.3 | 7.5 | 70 | 3048 | S135 | 33 | 6800 |

| D33×44, D36×50, D36 ×50 Series II | FS1#650 | 60.3 | 7.5 | 70 | 4572 | S135 | 33 | 6800 |

| D36×50, D36 ×50 Series II, D40×55 S3 | FS1#700 | 68 | 10.54 | 79 | 3048 | S135 | 44.2 | 6800 |

| D36×50, D36 ×50 Series II | FS1#700 | 68 | 10.54 | 79 | 4572 | S135 | 44.2 | 6800 |

| D50×100/Uni60×70 | FS1#900 | 73 | 9.5 | 82.55 | 3048 | S135 | 51.4 | 12240 |

| D50×100,D50×100A, D60×90 | FS1#900 | 73 | 9.5 | 82.55 | 4572 | S135 | 51.4 | 12240 |

| D50×100,D80×100Series II, D60×90 | FS1#800 | 88.9 | 9.35 | 92 | 4572 | S135 | 51.4 | 13600 |

| D100×120 Series II, D130×150, D60×90, D60×90 S3, D100×140, D100×140 S3 | FS1#1000 | 89 | 12 | 111 | 6096 | S135 | 60.2 | 20400 |

| D55×100 | #902 | 73 | 10 | 98 | 4572 | S135 | 52 | 17628 |

| D33×44, D36×50, D36 ×50 Series II | FS2 | 60.3 | 7.5 | 70 | 3048 | S135 | 33 | 6800 |

| D33×44, D36×50, D36 ×50 Series II | FS2 | 60.3 | 7.5 | 70 | 4572 | S135 | 33 | 6800 |

| D100×120 | FS2 | 88.9 | 10 | 104.8 | 6096 | S135 | 60.2 | 24480 |

| Model of the rig | Connection | OD of the Tube (mm) | Wall Thickness (mm) | OD of the joints/upset (mm) | Working Length (mm) | Weight (kg) | Tempering and Quenching Grade | Min Bending Radius (m) | Max Torque (N.m) |

| Case 6010 | Case 6010 | 52.3 | 6.5 | 57 | 3048 | S315 | 30 | 30 | |

| Case 6030 | Case 6030 | 60.3 | 7.1 | 66.7 | 3048 | 35 | S315 | 33 | 33 |

| Model of the rig | Connection | OD of the Tube (mm) | Wall Thickness (mm) | OD of the joints/upset (mm) | Working Length (m) | Tempering and Quenching Grade | Min Bending Radius (m) | Max Torque (N.m) |

| JT520 | DW 1.21 | 28.7 | 5 | 44.45 | 1.5 | S135 | 29.5 | 1220 |

| JT920/921 | DW 1.41 | 42.3 | 6.5 | 50.8 | 2 | S135 | 28 | 2929 |

| JT920L | DW 1.41 | 42.3 | 6 | 50.8 | 3.05 | S135 | 28.1 | 2929 |

| JT1720 | DW 1.69 | 54 | 6.5 | 63.5 | 3 | S135 | 35.8 | 6772 |

| JT2020/20 | DW 1.94 | 54 | 7.5 | 66.7 | 3 | S135 | 35.8 | 8240 |

| JT2720 | DW 1.94 | 60.3 | 7.5 | 70 | 3 | S135 | 40 | 7175 |

| JT25/30 | DW 2.11 | 60.3 | 8 | 70 | 3 | S135 | 40 | 10542 |

| JT25/2720M1/3020M1 | DW 2.11 | 60.3 | 8.5 | 76 | 3 | S135 | 40 | 18480 |

| JT4020 | DW 2.4 | 73 | 10 | 82.5 | 4.5 | S135 | 48.5 | 13440 |

| JT4020M1 | DW 2.59 | 73 | 10.5 | 89 | 4.5 | S135 | 51.4 | 18284 |

| JT7020/8020 | DW 3.27 | 88.9 | 9.35 | 101.6 | 4.5 | S135 | 59 | 27132 |

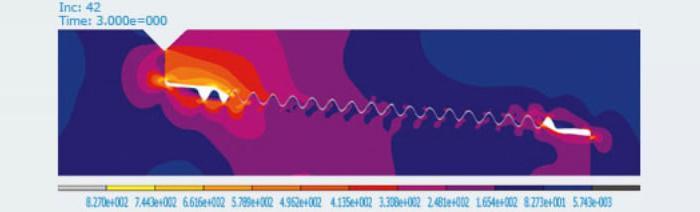

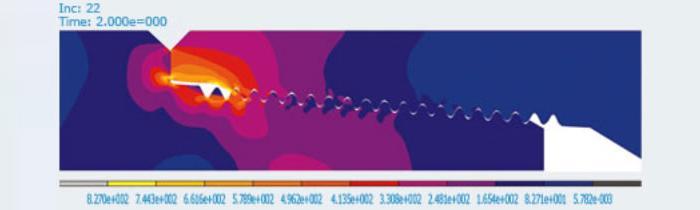

The thread of the trenchless drill pipe has two force-bearing regions to reduce the resistance during construction. Particularly offered for high torque, the drill rod is designed with large inner diameter for the drilling fluid to avoid thread deform.

1. Force-bearing shoulder A

2. Force-bearing shoulder B

DH joints

Inquiry Form

Wuxi Geotec Geological Equipment Co., Ltd.

Tel (National Sales):

+86-510-88552588

+86-510-88550355

Tel (International Sales): +86-510-88552380

Fax: +86-510-88552380